Chapter 9: Maintenance and Repair

Most components of the machine are very straightforward to work on. The following sections describe only those operations where the best working method may not be as obvious.

9.1. MACHINE COMPONENTS IDENTIFICATION

10 cfm Vacuum Pump Service

Most repairs or cleanup of the pumps can be made in place, in the machine. Tear-down is done as follows:

1. Remove the exhaust muffler bottle. If the pump exhausts through the side of the pylon, remove the nylon elbow. If the controls air exhausts into the pump exhaust line, disconnect this line.

2. Disconnect the inlet tube at the fitting on the pump head.

3. Remove the six bolts around the top of the pump head.

4. Lift the pump head off the pump body, being careful not to scratch the surfaces where the pump head and body mate.

5. Examine the four carbon vanes for serious chipping. They should slide freely in their slots. They must be inserted so that the bevel on their outer edges matches with the angle of the walls of the pump “barrel” or “cylinder.”

6. Carefully replace the pump cylinder head and retighten the six bolts in an alternating pattern (1 and 4, 2 and 5, 3 and 6). Replace inlet and exhaust fittings and lines.

21 cfm Vacuum Pump Service

1. Disconnect power to the machine.

2. Remove fan by gently levering it off with a flat bladed tool.

3. Remove eight (8) hex head cap screws holding end plate on unit.

4. Remove four (4) Phillips screws that hold end cap to end plate.

5. Using a puller tool remove the end plate.

6. Remove old vanes and check for foreign particles in pump chamber. Ensure that the four vane slots in the rotor are completely clean (clean with solvent as needed).

7. Install new vanes with beveled edges to match angle of pump body wall.

8. Install end plate (use a rawhide mallet or leaded rubber mallet to tap end plate down). There are two guide pins to line up on.

9. Install the eight (8) hex head cap screws to hold the end plate in place.

10. Using a ¾” deep well socket, placed over end of shaft, drive or set bearing fully to provide clearance for rotor to turn freely.

11. Install end cap with four (4) Phillips screws (making sure to have good seal).

12. Replace fan on shaft. Make sure fan does not hit Phillips screws of end cap.

13. Install fan guard with four (4) round head screws.

28/35 cfm Vacuum Pump Service

See Vacuum Pump Manual

Water-Ring Vacuum Pump Service (All Models)

See Vacuum Pump Manual and Drawings

Electric Vacuum Pump Removal

1. Mark III pumps are removed by unbolting the pump mount screws from under the machine, with the exception of the Gast 35 cfm/50 cfh model.

2. Gast 35 cfm/50 cfh pumps have rubber mounting “feet” located at two points under the front of the pump/motor mount and at three points under the rear of the mount.

3. From above, remove the screws holding the mount down to the rubber feet at both points under the front, but only at the center point, in the back. You can then slide the pump/motor out of the cabinet.

Thermocouple Replacement (Hot-bar Sealers Only)

Thermocouples are replaced by first disconnecting the two electrical leads inside the button box compartment, releasing the compression nut on the fitting at the bottom of the button box, and pulling the lead, in their flexible sheath, out of the button box. The sheet metal pan under the heat seal bar should be removed exposing the entry of the thermocouple sensor into the back of the heat seal bar. Remove the outer compression nut, and withdraw the thermocouple sensor. When installing the replacement thermocouple, certain precautions should be observed:

1. The thermocouple leads are vulnerable to kinking, so tight bends should be avoided.

2. When installing the sensor into the back of the heat seal bar, ensure that the small ferrule on the sensor is not lost. The tip of the sensor must also be fully “bottomed out” into the full depth of the well in the bar.

3. Note that the two leads are polar (+ and -) and must be connected to the temperature controller as shown in the circuit diagram.

Head Bearings Lubrication

Head bearings should be periodically lubricated at all rotating pivot points, and sliding surfaces. A heavy, water-proof grease is recommended – comparable to the food-grade lubricants provided with later model machines.

1. Pivot points can be opened up by first removing the shaft retainer, near the righthand end of the main pivot shaft (to which the operating handle is attached). This allows the shaft to slide sideways far enough to clean and lubricate the shaft bearings, link pivot pins and clamping bar pivot pins.

When replacing the shaft retainer, be sure that the excess play is removed by pushing the shaft to the left before tightening the retainer.

Flow Controls (Air Cylinders)

Pneumatic flow controls are provided on most air cylinders on the machine to regulate their speed. This serves two functions:

1. Both ends of the heat seal bar should extend and retract at the same speed, to avoid misaligning the bar.

2. Extension and retraction speed for all cylinders, should be controlled to avoid hammering at the end of the stroke.

The flow control meters the air being pushed out ahead of the moving piston in the cylinders, thereby controlling the piston’s speed. The flow control mounted on the end of the cylinder toward which the piston is traveling will control the stroke in that direction only. Cylinders without flow controls have internal bumpers to cushion their stoke.

Vacuum and Air Pressure Fittings

Most plastic vacuum tubes use white nylon compression fittings. The compression nut for these fittings can be adequately tightened with finger pressure and tools should never be used.

Air (pneumatic) tubes use “push-lock” fittings:

1. To install a tube into a fitting, simply push the tube into the fitting until it bottoms out.

2. To remove a tube, push down on the locking ring at the top of the fitting, and pull the tube out. To release the ring it is important to push it down evenly, from all sides.

Silicone Rubber Parts Service

The silicone rubber parts are very durable, and rarely need replacement. When necessary, the following tips apply:

1. Heat Seal Back-up Strip (Hot Bar)

This item can be removed by lifting the old strip out of the machined groove in the clamping jaw. Adhesives are not used for installation, as the rubber makes a tight fit in the groove. After installing the new rubber strip(s), adjustments may be necessary to tune for the most uniform heat seal, before the ends of the strip are trimmed flush with the clamping jaw. Make a few test seals in the Corr-vac® bags, and examine them carefully for signs of any low pressure areas in the heat seal. These can be remedied by slightly bunching up (or compressing) the rubber strip as

it is installed in the machined metal groove, in those low pressure areas.

Alternatively, the rubber can be slightly stretched in high pressure areas. This tuning process will result in the most uniform heat seals possible.

2. Heat Seal Back-up Strip (Impulse)

Once the ends of the strip become excessively scorched from heat, the strip can be turned over and reused for one additional operating period. Replacement is as follows:

- The groove in the jaw must first be clean and dry.

- Push one end of the rubber strip into the narrow portion of the groove, so that it is flush with the point where the groove widens out (near each end). Then push the remainder of the strip into the groove, working progressively across the jaw from the starting point. Avoid either stretching or compressing the rubber while you install it, or this may create an uneven thickness in the strip. Cut off the other end

of the strip, so that it is flush with its end of the narrow groove.

The Bag Clamping Strip can also be removed by pulling it out of its machined groove. The replacement should be thoroughly lubricated with soap water to ensure that it fully “bottoms out” in the groove. Start by lining up the die-cut opening in the rubber to exactly match the vacuum probe assembly. Slight stretching or bunching of the rubber may be necessary to ensure a perfect fit. Then push the rest of the strip fully into the groove.

To replace the rear probe seal, the metal seal retainer must first be removed. When installing the new seals, adjust the two mounting screws until the seal retainer is just snug on top of the seal. Excessive tightening of the screws will cause the seal to bulge outward and interfere with the vacuum probe and clamping jaw closure.

Heat Sealer Bar Teflon® Tape Service (Hot Bar)

Depending on the type of vacuum bag being used, some machines are equipped with an adhesive-backed strip of Teflon coated glass fiber tape, over the working face of the heat sealer bar. As the tape becomes worn, it will periodically have to be replaced.

1. Turn the SUPERVISOR’S KEY to the PROGRAMMING POSITION. Select any program number, then move through the DISPLAY screens until you find:

MAINTENANCE

SEAL BAR IN

2. Press the EDIT BUTTON to extend the sealer bar.

3. Peel the old tape off, and clean the old adhesive off the bar with a plastic pot scrubber and solvent. Dry thoroughly before mounting the new tape.

4. Avoid getting any grease or oil from your hands on the bar.

5. The tape should be lightly tacked to the working face of the bar at one end, with a one-inch overhang. Leave 5/8” of tape projecting below the bottom edge of the seal bar (when finished, the tape will be just short of the screw heads under the bar).

6. Work across the face of the bar, lightly tacking the tape down without wrinkles. With a smooth object, firmly tack the tape to the face of the bar, taking care to push it into the recess below the raised edge on the face of the bar.

7. Trim the tape ends flush with the ends of the bar.

8. Wrap and secure the tape back over the top and bottom of the bar, without wrinkles. Firmly tack down with a smooth object.

9. Press the EDIT BUTTON to retract the heat sealer bar, and then turn the SUPERVISOR’S KEY back to the RUN POSITION.

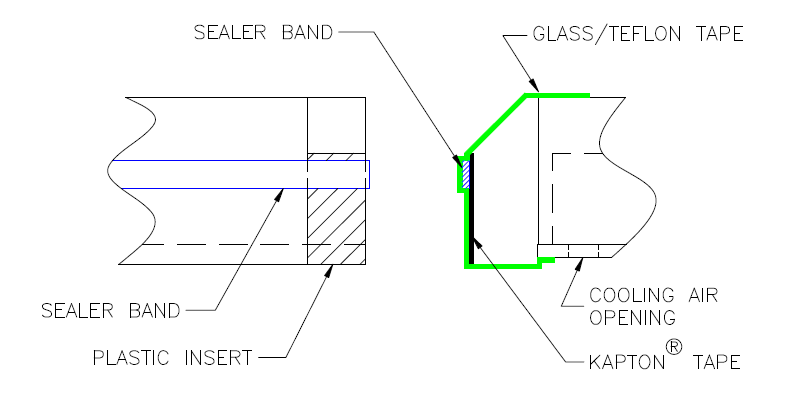

Impulse Heat Sealer Service

The impulse sealer heats by pulsing current through a sealer band (made of a resistance heating alloy), for a controlled period of time. The heat sealer bar remains engaged for an additional controlled period of time, during which the bag seal cools to a

stable condition. The sealer bar then retracts, releasing the bags.

The heat sealer bar is treated with a black anodized coating, to electrically insulate it from the current passing through the sealer band. Avoid scratching the coating surface, as electrical shorting and/or corrosion can eventually occur.

Additional insulation is provided by inserts of phenolic plastic, at each end of the sealer bar.

The surface directly behind the sealer band is also protected with a renewable layer of special Kapton® tape. It must occasionally be replaced, as needed, to avoid electrical shorting.

There are two styles of impulse sealer bands.

1. For bands with metal eyelets installed at each end, first remove the terminal screw from each end of the sealer bar. Install the new band with the colored dot facing outward (away from the sealer bar), and reinstall the two terminal screws.

2. For bands without eyelets, remove the hold-down screws, and the hold-down covers at each end of the sealer bar. Insert the short tab of the new band into the fitting at each end, with the hold-down screws finger tight. Then tighten both screws.

Heat sealer tape must be periodically replaced, as needed. It should be installed as shown below, making sure that it does not cover the cooling air openings on the underside of the bar. Access to the bar can be improved, as follows:

1. Turn the SUPERVISOR’S KEY to the PROGRAMMING POSITION. Select any program number, then move through the DISPLAY screens until you find:

MAINTENANCE

SEAL BAR IN

Press the SET BUTTON to extend the sealer bar.

2. To retract the heat sealer bar, press the SET BUTTON, then turn the SUPERVISOR’S KEY back to the RUN POSITION.

Automatic Jaw Opener Adjustment

Adjustments to the jaw opening action can be made at the small air flow control, located on the auto jaw opener cylinder.

1. If the machine jaw doesn’t fully open, slightly increase air flow at the flow control.

2. If the jaw opens too fast (and bounces partially shut), slightly reduce air flow at the flow control.